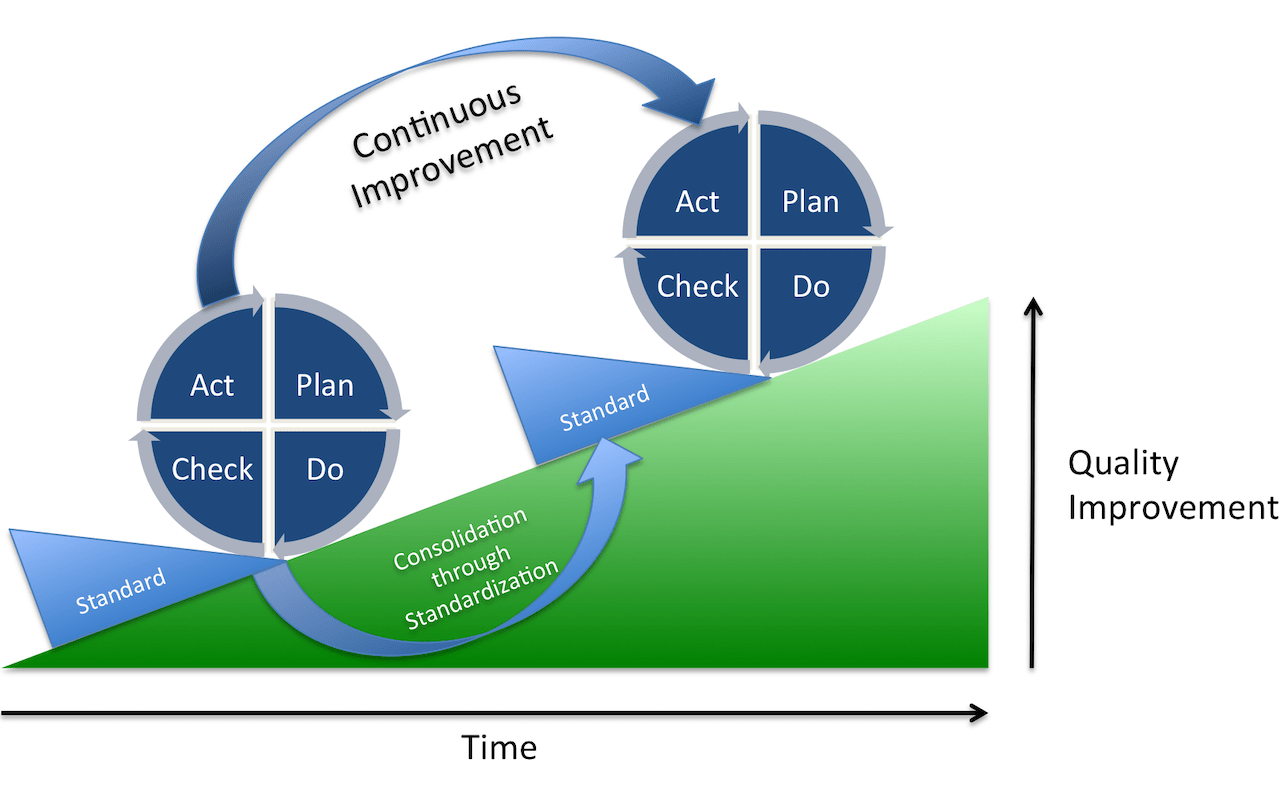

The Deming Cycle, also known as the PDCA (Plan-Do-Check-Act) Cycle, is a powerful methodology that can help individuals and organizations achieve continuous improvement in various areas of their lives. The PDCA Cycle was developed by Dr. W. Edwards Deming, an American statistician, in the 1950s, and it has since become a popular framework for quality management and process improvement.

The PDCA Cycle consists of four phases: Plan, Do, Check, and Act. Each phase is critical to the success of the overall process, and they are all interconnected and cyclical. In this chapter, we will explore each phase in detail, including its key principles, benefits, and practical applications.

Plan

The first phase of the PDCA Cycle is Plan. This phase involves setting goals, defining objectives, and developing a plan of action to achieve those goals. During the planning phase, it is essential to identify the key stakeholders and gather their input to ensure that the plan aligns with their needs and expectations.

The Plan phase requires a thorough understanding of the current situation and the desired future state. This requires the use of data and analysis to identify the root cause of problems and potential opportunities for improvement. The Plan phase also involves the development of a detailed project plan, which outlines the steps needed to achieve the goals, as well as the resources required.

One of the key benefits of the Plan phase is that it enables individuals and organizations to clarify their objectives and develop a roadmap to achieve them. By taking the time to plan, individuals and organizations can avoid potential pitfalls and ensure that they are focusing their efforts on the most critical areas.

Do

The second phase of the PDCA Cycle is Do. This phase involves the execution of the plan developed in the Plan phase. During the Do phase, individuals and organizations implement the actions identified in the project plan and monitor progress towards the goals.

The Do phase requires a strong focus on execution and communication. It is essential to ensure that all stakeholders are aware of their roles and responsibilities and that everyone is working towards the same objectives. Communication and collaboration are critical during the Do phase to ensure that any issues or roadblocks are quickly identified and addressed.

One of the key benefits of the Do phase is that it provides individuals and organizations with the opportunity to test their assumptions and validate their hypotheses. By taking action and monitoring progress, individuals and organizations can quickly identify what is working and what is not, and adjust their approach accordingly.

Check

The third phase of the PDCA Cycle is Check. This phase involves the evaluation of the results achieved during the Do phase. During the Check phase, individuals and organizations assess whether they have achieved their goals and objectives and identify any areas for improvement.

The Check phase requires a rigorous approach to data analysis and evaluation. It is essential to measure progress towards the goals and compare the actual results with the expected outcomes. The Check phase also involves the identification of any gaps or deviations from the plan, and the development of corrective actions to address them.

One of the key benefits of the Check phase is that it enables individuals and organizations to gain valuable insights into their performance and identify opportunities for improvement. By taking a data-driven approach to evaluation, individuals and organizations can make informed decisions about how to optimize their performance and achieve their goals.

Act

The fourth and final phase of the PDCA Cycle is Act. This phase involves the implementation of the corrective actions developed in the Check phase. During the Act phase, individuals and organizations make the necessary changes to their processes or systems to improve their performance and achieve their goals.

The Act phase requires a focus on continuous improvement and a willingness to learn from experience. It is essential to monitor progress after implementing the corrective actions and to evaluate the effectiveness of the changes made. The Act phase also involves the identification of any new opportunities for improvement, and the development of new plans to capitalize on those opportunities.

One of the key benefits of the Act phase is that it enables individuals and organizations to achieve continuous improvement over time. By regularly evaluating performance and making adjustments, individuals and organizations can optimize their processes and systems and achieve their goals more efficiently and effectively.

Benefits of the PDCA Cycle

The PDCA Cycle has several benefits for individuals and organizations. One of the most significant benefits is that it provides a structured approach to continuous improvement. By following the four phases of the PDCA Cycle, individuals and organizations can ensure that they are systematically evaluating their performance, identifying areas for improvement, and making the necessary changes to optimize their processes and systems.

Another benefit of the PDCA Cycle is that it promotes collaboration and communication. The PDCA Cycle requires input and feedback from stakeholders at each phase, which helps to ensure that everyone is aligned towards the same objectives. This can help to reduce misunderstandings and conflicts, and promote a culture of continuous improvement and teamwork.

The PDCA Cycle is also a flexible methodology that can be applied in various contexts. It is commonly used in quality management and process improvement, but it can also be applied in personal and professional settings. For example, individuals can use the PDCA Cycle to set goals, develop action plans, monitor progress, and make adjustments to achieve their personal and professional objectives.

Pros and cons of PDCA cycle

The PDCA Cycle, also known as the PDCA (Plan-Do-Check-Act) Cycle, is a powerful methodology for achieving continuous improvement in various areas of personal and professional life. While there are many benefits to using the PDCA Cycle, there are also some potential drawbacks to consider. Here are some pros and cons of the PDCA Cycle:

Pros of the PDCA Cycle

- Provides a structured approach to continuous improvement: The PDCA Cycle is a systematic and cyclical approach to evaluating performance, identifying areas for improvement, and making the necessary changes to optimize processes and systems. By following the four phases of the PDCA Cycle, individuals and organizations can ensure that they are taking a rigorous and comprehensive approach to continuous improvement.

- Promotes collaboration and communication: The PDCA Cycle requires input and feedback from stakeholders at each phase, which helps to ensure that everyone is aligned towards the same objectives. This can help to reduce misunderstandings and conflicts, and promote a culture of continuous improvement and teamwork.

- Can be applied in various contexts: The PDCA Cycle is a flexible methodology that can be applied in quality management, process improvement, and personal and professional development. Individuals and organizations can use the PDCA Cycle to set goals, develop action plans, monitor progress, and make adjustments to achieve their objectives.

- Enables continuous improvement over time: By regularly evaluating performance and making adjustments, individuals and organizations can optimize their processes and systems and achieve their goals more efficiently and effectively.

Cons of the PDCA Cycle

- Can be time-consuming: The PDCA Cycle requires a thorough understanding of the current situation, the development of a detailed project plan, rigorous data analysis, and evaluation of results. This can be a time-consuming process, especially for complex or large-scale projects.

- Requires a significant investment of resources: The PDCA Cycle requires resources such as personnel, technology, and financial investments to implement. This can be a significant burden for small or resource-constrained organizations.

- May not be suitable for all contexts: The PDCA Cycle is a comprehensive approach to continuous improvement, and it may not be necessary or appropriate for all contexts. For example, some organizations may prefer to use a more streamlined approach to improvement that is more suited to their needs and resources.

- May not always lead to immediate results: The PDCA Cycle is a long-term approach to continuous improvement, and it may not always lead to immediate results. It requires patience and persistence to achieve significant improvements over time.

Alternative approaches

While the PDCA Cycle is a powerful approach to achieving continuous improvement, there are also alternative approaches that may be more suitable for certain contexts or situations. Here are a few examples:

- Lean Six Sigma: Lean Six Sigma is a methodology that combines two popular approaches to process improvement – Lean and Six Sigma. Lean focuses on reducing waste and increasing efficiency, while Six Sigma focuses on reducing variability and improving quality. Together, these methodologies provide a comprehensive approach to process improvement that can lead to significant results.

- Agile: Agile is an iterative approach to project management that emphasizes flexibility, collaboration, and customer satisfaction. Agile is often used in software development and other complex projects where requirements are likely to change over time. Agile emphasizes regular communication, short feedback loops, and continuous improvement.

- Total Quality Management (TQM): Total Quality Management is a comprehensive approach to quality management that emphasizes customer satisfaction, employee involvement, and continuous improvement. TQM is focused on creating a culture of quality within an organization and involves all employees in the process of continuous improvement.

- Kaizen: Kaizen is a Japanese term that means “continuous improvement.” Kaizen is focused on making small, incremental improvements to processes and systems over time. Kaizen emphasizes employee involvement, collaboration, and a focus on customer needs.

- Design Thinking: Design Thinking is a human-centered approach to problem-solving that emphasizes empathy, creativity, and experimentation. Design Thinking involves understanding the needs of users, generating ideas, prototyping and testing solutions, and iterating based on feedback.

Each of these alternative approaches has its own strengths and weaknesses and may be more or less suitable depending on the context and goals of the project or organization. It is important to consider the specific needs and constraints of the situation when choosing an approach to continuous improvement.

Applications for the PDCA cycle

The PDCA Cycle can be applied in various contexts where continuous improvement is desired. Here are some examples of good applications for the PDCA Cycle:

- Quality management: The PDCA Cycle was originally developed for quality management, and it remains a popular approach for improving quality in manufacturing, healthcare, and other industries. By using the PDCA Cycle, organizations can systematically identify and address quality issues, monitor progress, and make the necessary changes to improve quality over time.

- Process improvement: The PDCA Cycle is also well-suited for process improvement initiatives. By following the four phases of the PDCA Cycle, organizations can systematically identify and address process inefficiencies, monitor progress, and make the necessary changes to optimize processes over time.

- Project management: The PDCA Cycle can be used in project management to ensure that projects are executed efficiently and effectively. By using the PDCA Cycle, project teams can set clear objectives, develop a detailed project plan, monitor progress, and make the necessary changes to ensure that the project is completed on time and within budget.

- Personal and professional development: The PDCA Cycle can be applied in personal and professional development to achieve personal and professional goals. By using the PDCA Cycle, individuals can set clear goals, develop action plans, monitor progress, and make the necessary changes to achieve their objectives over time.

- Customer service: The PDCA Cycle can be used to improve customer service by systematically identifying and addressing customer issues, monitoring progress, and making the necessary changes to ensure that customers are satisfied over time.

- Risk management: The PDCA Cycle can be used in risk management to identify and address potential risks, monitor progress, and make the necessary changes to mitigate risks over time.

These are just a few examples of the many applications of the PDCA Cycle. The PDCA Cycle is a flexible methodology that can be applied in various contexts where continuous improvement is desired. By following the four phases of the PDCA Cycle, individuals and organizations can achieve their objectives more efficiently and effectively over time.

Conclusion

The PDCA Cycle is a powerful methodology that can help individuals and organizations achieve continuous improvement in various areas of their lives. The four phases of the PDCA Cycle – Plan, Do, Check, and Act – provide a structured approach to evaluating performance, identifying areas for improvement, and making the necessary changes to optimize processes and systems.

By following the PDCA Cycle, individuals and organizations can promote a culture of continuous improvement, collaboration, and communication. They can also achieve their goals more efficiently and effectively, and adapt to changing circumstances and environments. Whether applied in quality management, process improvement, or personal and professional development, the PDCA Cycle can help individuals and organizations achieve their full potential.